Why Are Planes Delayed? The Surprising Impact of Tight Company Budgets on Aircraft Production

Ever wondered why your flight gets delayed, or why new planes seem to take forever to roll off the assembly line? It’s not always about weather or technical glitches. Sometimes, the root cause is a lot closer to the company’s own wallet. When a major manufacturer starts pinching pennies—especially when it comes to its own workforce—the ripple effects can be massive.

How Does Cutting Worker Costs Slow Down Plane Manufacturing?

Let’s get real: building a commercial aircraft is a high-stakes, high-skill operation. Every bolt, panel, and wire needs a practiced hand. When a company tries to save money by freezing wages, reducing overtime, or skimping on benefits, morale takes a nosedive. Workers who feel undervalued are less likely to go the extra mile, and experienced machinists might even leave for better opportunities elsewhere.

A recent study from the International Association of Machinists and Aerospace Workers found that companies with stagnant wage growth saw a 15% higher turnover rate among skilled laborers. That’s not just a number—it’s hundreds of years of collective experience walking out the door. The result? Production lines slow down, mistakes creep in, and deadlines get missed.

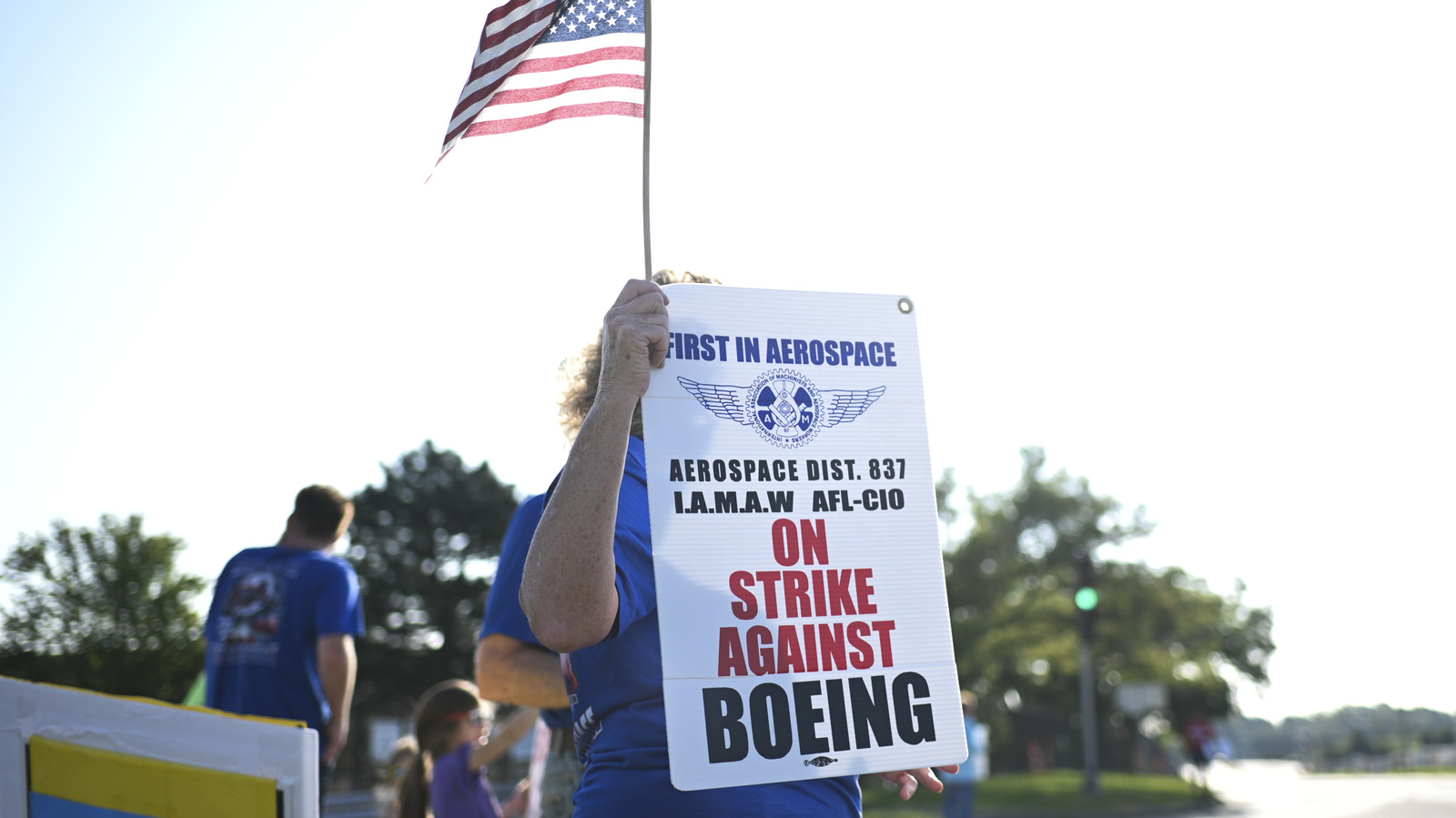

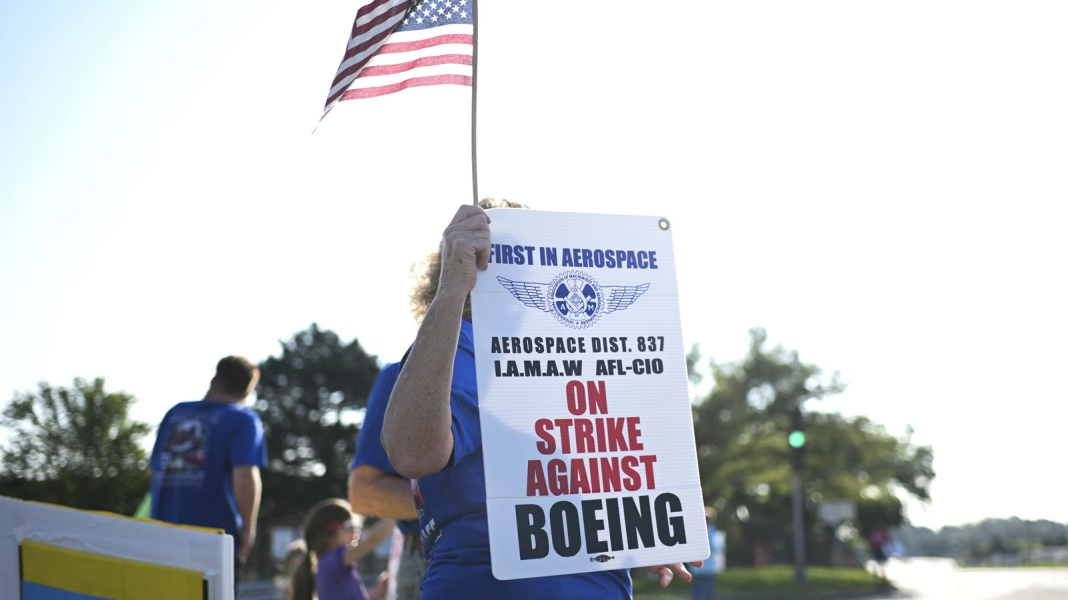

What Happens When Labor Disputes Hit the Assembly Line?

Labor disputes aren’t just about picket signs and tense negotiations. When machinists and engineers feel their concerns are ignored, strikes can bring entire factories to a standstill. Take the recent situation where a machinist union approved an offer that, according to reports, the company never officially made. Confusion like this doesn’t just frustrate workers—it throws schedules into chaos.

During a strike, even a short one, the backlog can snowball. Every day lost means rescheduling suppliers, rebooking test flights, and pushing back delivery dates for airlines. According to a 2023 report from the Aerospace Industries Association, even a two-week work stoppage can set production back by months, not days.

Why Do These Delays Matter to Travelers and Airlines?

It’s easy to think that plane production delays are just a headache for manufacturers. But the truth is, everyone feels the pinch. Airlines waiting for new planes can’t expand routes or replace aging jets, which means fewer seats and higher ticket prices for travelers. In 2022, global airline capacity was down by nearly 20% compared to pre-pandemic levels, partly because new aircraft deliveries lagged behind schedule.

For airlines, every grounded plane is lost revenue. For passengers, it means more crowded flights and less flexibility. And for the workers on the ground, it’s a reminder that their expertise is the backbone of the entire industry.

Are There Smarter Ways to Balance Budgets Without Sacrificing Quality?

Here’s the million-dollar question: can companies save money without cutting corners on their workforce? Experts say yes, but it takes a shift in mindset. Instead of slashing pay or benefits, some manufacturers are investing in cross-training programs, automation that supports (not replaces) skilled workers, and profit-sharing incentives that reward productivity.

For example, one major aerospace firm recently launched a mentorship initiative pairing veteran machinists with new hires. The result? Fewer errors, faster ramp-up times, and a noticeable boost in team morale. It’s proof that investing in people pays off—sometimes literally.

What’s the Real Cost of Short-Term Savings?

It’s tempting for companies to focus on quarterly earnings and immediate savings. But the hidden costs—lost expertise, production delays, and damaged reputations—often outweigh the benefits. A 2023 analysis by Deloitte found that manufacturers who prioritized workforce stability saw 12% higher long-term profitability compared to those who relied on aggressive cost-cutting.

The big takeaway? Building planes isn’t about perfection—it’s about smarter adjustments. Start with one change this week, and you’ll likely spot the difference by month’s end.