EV insurance costs set to climb as battery repairs lag behind replacements

EV drivers told premiums will rise until battery repairs are more feasible

EV drivers told premiums will rise until battery repairs are more feasible

Insurance premiums for electric cars will continue to rise unless the UK can find a cost-effective way of repairing damaged batteries rather than replacing them, warns Thatcham Research, an organisation owned by motor insurers.

This is because the component is worth up to 55% of the value of a new EV – and more as the vehicle ages and depreciates. As a result, some EVs that sustain damage to their battery in an accident are being written off.

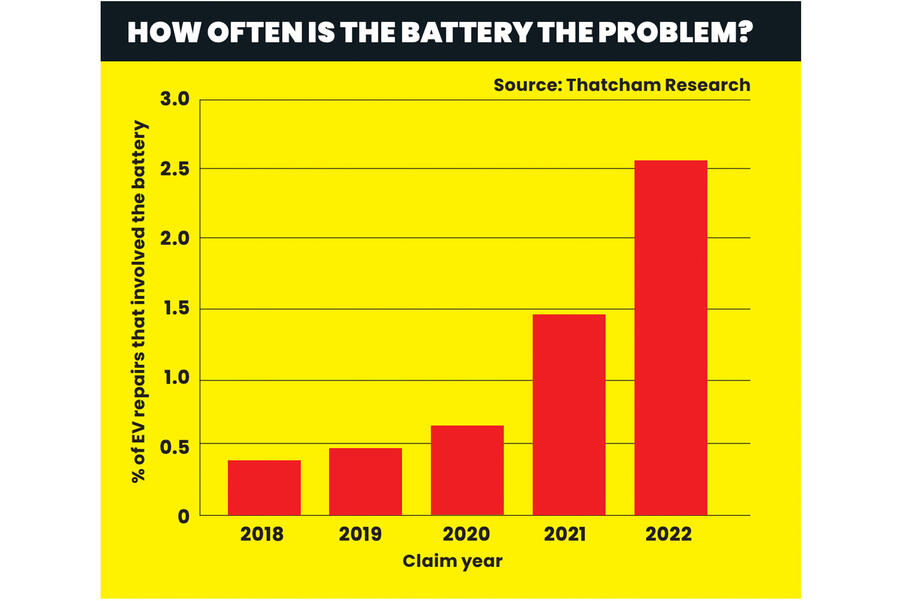

While the number of repairs is rising, it remains a very low proportion of total EV repairs, at 2%. Thatcham Research warns that as the number of EVs in the UK increases beyond today’s 1.5 million, it’s essential the UK develops a battery repair and refurbishment industry that will help to keep the costs of claims down.

Dan Harrowell, principal engineer of advanced technologies at Thatcham Research, said: “There’s a lot of discussion around recycling batteries, but as the insurance industry we’re focused instead on the repair, refurbishment and remanufacture of batteries.

“To maintain parity with ICE vehicles, we need battery refurbishment and repairs to be done by independent repairers, as happens in the replacement engine sector. The risk is that unless industry develops the skills to do this work, as we hit scale and as EVs age, writeoffs will be more considerable.”

Insurers are also concerned that replacing a damaged battery with a new one puts a policy holder in a better position than they were before their accident, because the car will be worth more with a new battery fitted.

“This falls into the debate the industry is having about ‘betterment’,” said Harrowell. “Refurbishment to a level equal to the original battery would solve a lot of our challenges.”

There are signs the industry is taking notice. In March, Cox Automotive and DHL combined to launch a centre for the repair and remanufacture of EV batteries for fleets. Located in Rugby, the 35,000sq ft facility has the capacity to process thousands of batteries a year.

Paul Stone, managing director of DHL Supply Chain UK, said: “This cooperation represents a major step forward in creating a scalable circular economy for batteries in the UK.”

Meanwhile, Grantham-based Autocraft Solutions, a remanufacturer of engines, is also repairing and refurbishing EV batteries. However, crucially for insurers concerned about betterment, it is restoring them to the condition they were in immediately prior to their failure.

“We accept that batteries don’t go back to exactly the way they were when new because of the way their chemistry changes,” said Autocraft engineering and quality director Sara Ridley. “Instead, we aim to put them back as close as possible to where they should be for the age and type of battery.”

The company is repairing and refurbishing up to 3000 batteries a year. Each is around 50% cheaper than its new equivalent but this saving varies according to how long it takes to repair.

Ridley said: “Batteries are being prematurely scrapped because people don’t know what’s wrong with them or whether they are safe. We can establish this and fix them. Insurers need that confidence.”

Spirit Airlines pilot ignores warnings and flies dangerously close to Air Force One

Polestar embraces bold car features as 80 percent of drivers adapt and love the...

Swedish EV brand designs divisive but memorable cars, says CEO Michael Lohscheller

Swedish EV brand designs divisive but memorable cars, says CEO Michael Lohscheller

Polestar is happy to have polarising features on its cars as a way of standing out against the competition.

These include the likes of the lack of rear window on the Polestar 4, which instead has a camera to give the driver a digital rear view.

At the recent Munich motor show, CEO Michael Lohscheller told Autocar: "80% of the customers get used to very quickly and then they like it – but I will say there are also people who don't like it.

"So in a way, the car is polarising, which sometimes is really, really good, because you don't want a car that is 'kind of all right'.

"Everybody has a 'kind of all right' car, but you want a very specific car. That's what the Polestar 4 is doing: there are people who drive it and love it, then there are 20% who say 'it's absolutely not for me'.

"But that's okay; it's totally okay. We don't want a car where everybody says, 'well, I kind of like it'. No, you have to love it or not.

"So I think actually [the 4] is an exceptionally successful [design]."

Lohscheller said the new Polestar 5 continued the trend for the Swedish brand of "making a statement" in its positioning and execution.

It also continued a trend for Polestar in being based on a different platform to other models in the range, meaning all five Polestars to date have been built on different underpinnings.

Lohscheller said that trend would change and the brand "would harmonise over time" and launch more related models.

The European-built Polestar 7 smaller SUV and next-generation Polestar 2 are likely to be the first to share a platform.

"The more you standardise, the better your quality," Lohscheller added.

More broadly on European production, Lohscheller said it will reduce Polestar's CO2 footprint by bringing local production to its largest market. It will also allow it to get its cars to customers quicker in the UK, its biggest single market.

He remains committed to the brand's 'asset-light' business model, which means sourcing platforms, technology and factories in which to build cars from other companies.

This will be "the future of the automotive industry", according to Lohscheller, in order for car companies to be more efficient and leverage more from each other.

Lohscheller was speaking just days after Polestar posted a quarterly loss of more than $1 billion, including a write-down cost in excess of $700 million on the US-built Polestar 3, due to the impacts of weaker than expected sales and US trade tariffs.

He insisted his focus is on the operational business and said that revenue growth of 56%, a positive gross margin for the first time and reduced costs are signs that Polestar is heading in the right direction in terms of establishing itself as a profitable business.

"The underlying operational business clearly improved in the first half of the year," he said. "That's good to see."

Boeing Faces 3.1 Million Fine After 737 Max Door Plug Blowout and Safety Interference

GAZ off road sedan transformed with 14 reinforced panels for rugged adventures

Audi history revealed the story behind the iconic four rings logo

Dacia Duster Hybrid Van Launches With Impressive Cargo Space and Versatile Power Options

New Duster Cargo offers choice of mild-hybrid or full-hybrid power; deliveries begin this winter

New Duster Cargo offers choice of mild-hybrid or full-hybrid power; deliveries begin this winter

Dacia has revealed a van variant of its new Duster SUV, priced from £22,995 (excluding VAT).

The van trades the passenger version’s rear seats for a flat wooden floor and four lashing points for securing large cargo, and the load bay is separated from the cockpit by a mesh bulkhead.

The tweaks give the commercial Duster an 1149-litre load capacity - almost as much as the similarly conceived Toyota Corolla Commercial, which is the closest comparable car-based van currently on sale.

To ensure privacy, the electric rear windows are swapped for fixed items tinted opaque black, and there's a removable load cover.

The Duster Cargo is available with a choice of two petrol powertrains: a mild hybrid with four-wheel drive and a full hybrid that drives only the front wheels.

The mild hybrid uses a turbocharged 1.2-litre three-cylinder engine that puts out 128bhp and 170lb ft of torque. This is paired with a six-speed manual gearbox and yields 46.3mpg.

The full hybrid, meanwhile, uses a naturally aspirated 1.8-litre four-pot that, together with two electric motors, produces 153bhp and 151bhp. This set-up nets 59mpg.

Payload capacities are rated at 410kg for the mild hybrid and 430kg for the full hybrid.

However, the mild hybrid can tow up to 1.5 tonnes, while the full hybrid is capped at half that.

The Duster Cargo will be offered in one trim level, Expression, bringing 17in alloy wheels, a six-way-adjustable driver’s seat and a 10.1in infotainment touchscreen with Apple CarPlay and Android Auto.

The mild hybrid costs £22,995, while the full hybrid is £600 more.

Customer deliveries are earmarked to begin before the end of the year.

RV Laws You Need to Know Before Riding in a Camper Trailer

Changan Deepal S07 Challenges Tesla Model Y with Impressive Range and Heritage

Can the latest Chinese entrant make a dent in the Tesla Model Y's popularity? Meet the Changan Deepal S07. Yup, that’s right, another Chinese firm has entered the UK market, and yes, I can hear your sighs from here. But bear with me, because Changan actually has heritage and its Deepal brand already has merits.So, to clarify: Changan is the parent company here. It’s the oldest Chinese car manufacturer, no less, having been producing cars for its domestic market since 1984. Not only that, but it’s had a design centre in Turin since 2001, an R&D centre in the UK since 2010 and a further design centre in Munich since 2021 (the latter dedicated to the Avatr luxury brand, which will also enter the UK market in time).For further evidence of Changan's dedication to its European and UK ventures, it has promised a €2 billion investment by 2030 and has been open about its intentions to open a manufacturing facility in Europe.Changan launched the Deepal brand in 2022, and here we have its first UK-market model, the S07. This 4.75m-long, five-seat electric SUV uses a CATL-sourced 75kWh (usable) nickel-manganese-cobalt battery, for a WLTP range of 295 miles. Currently only available as a rear-wheel-drive model, it’s aimed squarely at the Tesla Model Y, Skoda Enyaq, Hyundai Ioniq 5 and BYD Sealion 7.

Can the latest Chinese entrant make a dent in the Tesla Model Y's popularity? Meet the Changan Deepal S07. Yup, that’s right, another Chinese firm has entered the UK market, and yes, I can hear your sighs from here. But bear with me, because Changan actually has heritage and its Deepal brand already has merits.So, to clarify: Changan is the parent company here. It’s the oldest Chinese car manufacturer, no less, having been producing cars for its domestic market since 1984. Not only that, but it’s had a design centre in Turin since 2001, an R&D centre in the UK since 2010 and a further design centre in Munich since 2021 (the latter dedicated to the Avatr luxury brand, which will also enter the UK market in time).For further evidence of Changan's dedication to its European and UK ventures, it has promised a €2 billion investment by 2030 and has been open about its intentions to open a manufacturing facility in Europe.Changan launched the Deepal brand in 2022, and here we have its first UK-market model, the S07. This 4.75m-long, five-seat electric SUV uses a CATL-sourced 75kWh (usable) nickel-manganese-cobalt battery, for a WLTP range of 295 miles. Currently only available as a rear-wheel-drive model, it’s aimed squarely at the Tesla Model Y, Skoda Enyaq, Hyundai Ioniq 5 and BYD Sealion 7.Directional wheels are disappearing and car enthusiasts are not happy