How Are Robots Tackling the Problem of Downtime in the Workplace?

Let’s face it: downtime is the silent productivity killer, whether you’re running a factory or managing a fleet of delivery bots. For human workers, a quick coffee break or a lunch hour is all it takes to recharge. But what about androids and robots? Traditionally, when a robot’s battery runs low, it’s game over until someone swaps it out or plugs it in. That’s a huge bottleneck—especially as businesses rely more on automation to keep things humming around the clock.

Can Robots Really Change Their Own Batteries?

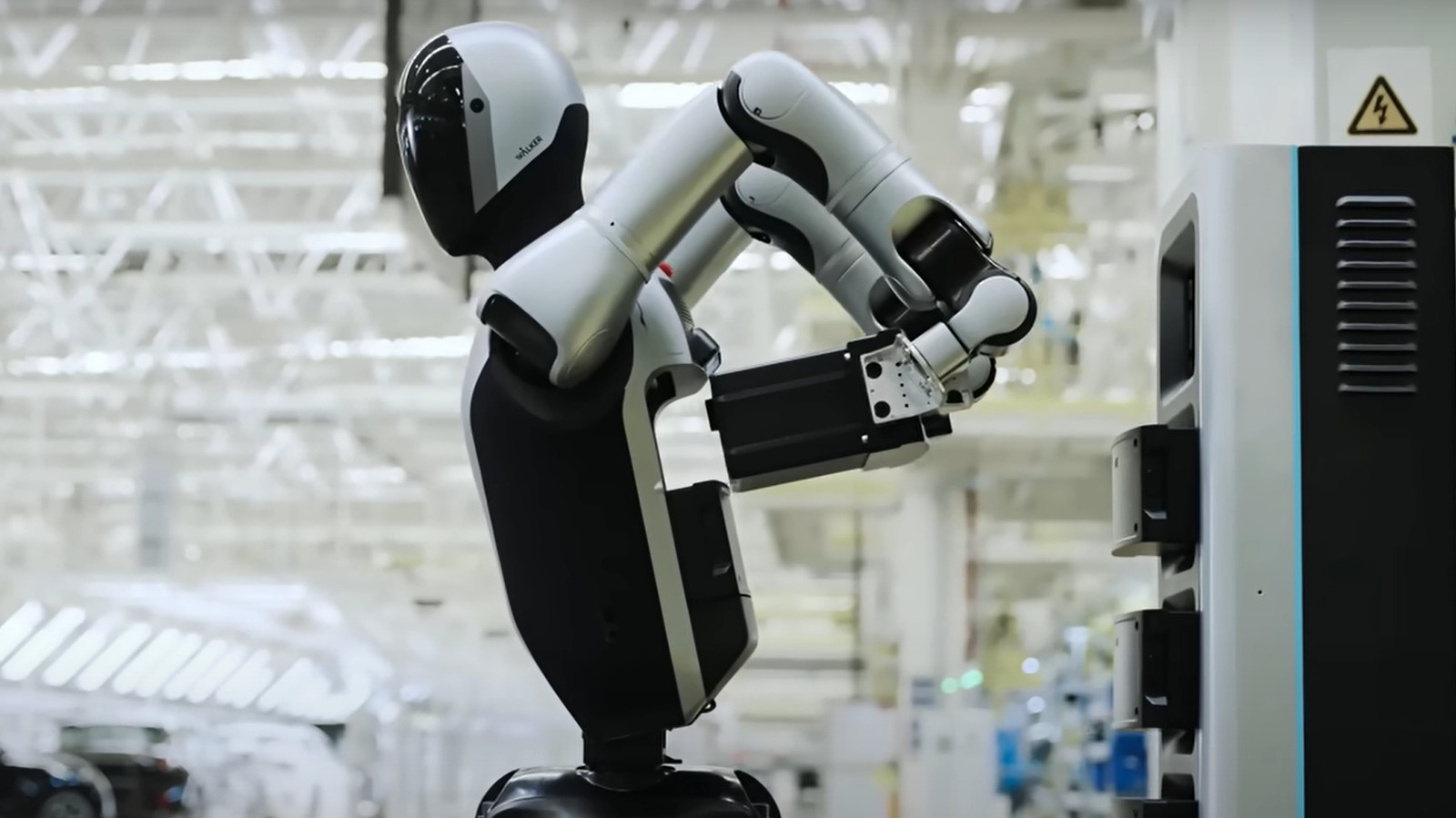

It sounds like something out of a sci-fi movie, but robots are now learning to handle their own battery swaps. In China, for example, engineers have developed humanoid robots that can detect when their battery is running low, navigate to a charging station, and physically remove and replace their own power packs—all without human help. The process is surprisingly smooth: the robot recognizes its energy needs, carefully detaches the depleted battery, and slots in a fresh one, ready to get back to work in minutes.

Why Is Autonomous Battery Swapping a Game-Changer?

The implications here are huge. First, it slashes downtime to nearly zero. Instead of waiting for a technician, robots can keep themselves powered up and on task. This means factories, warehouses, and even hospitals can run more efficiently, with fewer interruptions and less need for human oversight.

There’s also a safety angle. Manual battery changes can be risky—heavy batteries, exposed electrical contacts, and the ever-present risk of human error. Letting robots handle their own power management reduces these hazards and frees up skilled workers for more valuable tasks.

What Does This Mean for the Future of Work?

If you’re picturing a future where robots outnumber humans on the shop floor, you’re not alone. According to the International Federation of Robotics, global robot installations hit a record high in recent years, with China leading the charge. As these machines become more self-sufficient, businesses can scale up automation without worrying about constant maintenance interruptions.

But it’s not just about efficiency. Self-swapping batteries open the door for robots to work in environments that are hazardous or remote—think disaster zones, deep mines, or even space stations—where human intervention is difficult or dangerous.

Are There Any Downsides or Challenges?

Of course, no technology is perfect out of the gate. Designing robots that can safely and reliably change their own batteries requires advanced sensors, precise motor control, and robust safety protocols. There’s also the question of standardization: will every robot use the same kind of battery, or will we end up with a patchwork of incompatible systems?

And let’s be honest—watching a humanoid robot pop out its own battery can be a little unsettling. The uncanny valley is real, and as robots become more autonomous, society will need to grapple with new questions about trust, safety, and the role of machines in our daily lives.

How Can Businesses Prepare for This Shift?

If you’re running a business that’s considering automation, now’s the time to think ahead. Investing in robots with self-maintenance capabilities could mean fewer headaches down the road. It’s worth consulting with robotics experts to ensure your systems are future-proof and that your staff is trained to work alongside these new colleagues.

The big takeaway? Robot self-maintenance isn’t about perfection—it’s about smarter adjustments. Start with one change this week, and you’ll likely spot the difference by month’s end.