Could an Engine Really Run Without Oil?

Imagine popping the hood and seeing an engine that doesn’t need oil. No more messy oil changes or worrying about leaks. Sounds like a mechanic’s dream, right? That was the promise behind a handful of ambitious engine designs that tried to ditch oil altogether. On paper, these ideas looked like game-changers. But when engineers put theory to the test, reality had other plans.

What Made Oil-Free Engines Seem Possible?

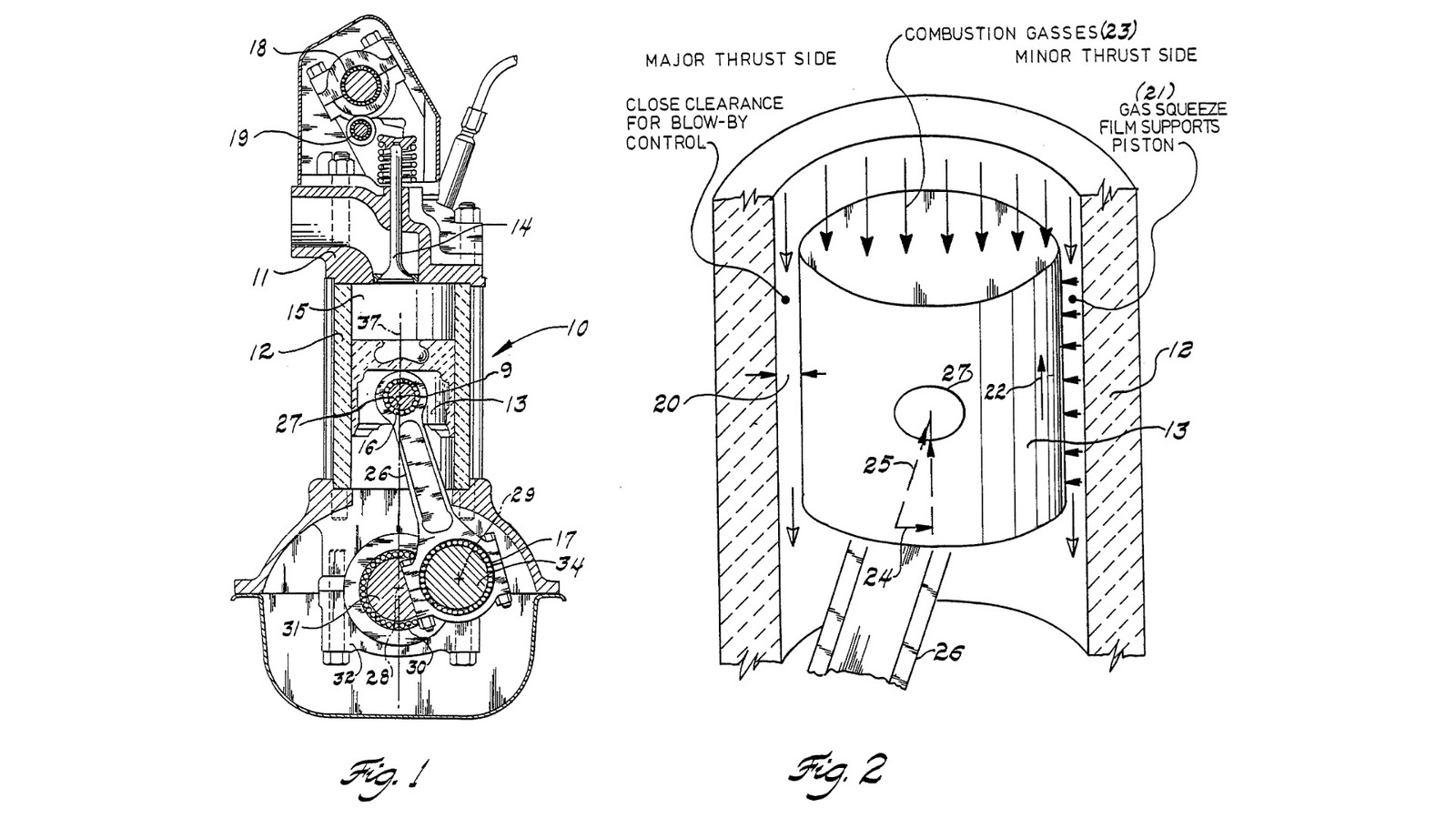

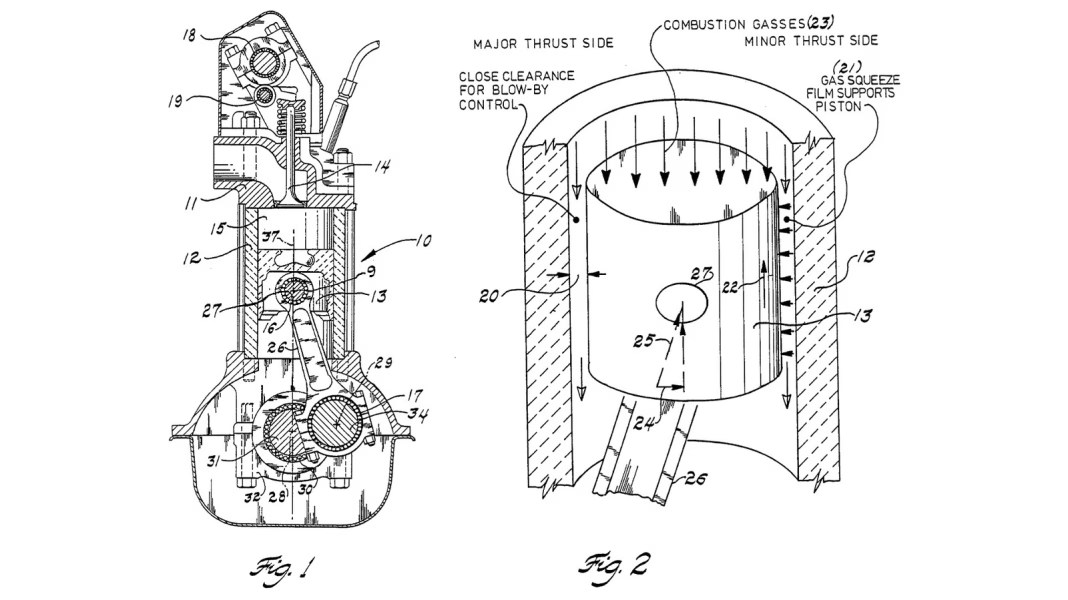

The basic idea was simple: eliminate the need for oil by using advanced materials or clever engineering tricks to reduce friction. Some inventors experimented with self-lubricating ceramics or special coatings that could, in theory, handle the intense heat and pressure inside an engine. Others tried to redesign moving parts so they’d glide past each other with minimal resistance.

The appeal was obvious. Oil is a hassle. It breaks down over time, collects dirt, and can cause catastrophic engine failure if it runs low. If you could build an engine that didn’t need oil, you’d save money, reduce maintenance, and maybe even help the environment by cutting down on waste oil.

Why Did These Oil-Free Engines Struggle in the Real World?

Here’s where things got tricky. Engines are brutal environments. Temperatures can soar above 500 degrees Fahrenheit, and the forces at play are enough to wear down even the toughest metals. While ceramic coatings and self-lubricating materials sounded promising, they just couldn’t handle the relentless pounding of daily driving.

Real-world testing revealed a laundry list of problems. Parts wore out faster than expected. Friction increased, not decreased, leading to overheating and efficiency losses. And when things did go wrong, repairs were often more complicated and expensive than with a traditional engine. In short, the dream of an oil-free engine kept running into the same brick wall: nothing beats oil’s ability to cushion, cool, and clean moving parts.

Are There Any Success Stories or Lessons Learned?

It wasn’t all wasted effort. Some of the materials and coatings developed for these oil-free engines found their way into other industries. For example, ceramic bearings and advanced polymers are now used in high-performance racing and aerospace applications, where every ounce of efficiency counts. And the push to reduce friction inspired automakers to develop better oils and more efficient engine designs.

One interesting takeaway: even though a truly oil-free engine hasn’t hit the mainstream, the quest for one has made today’s engines more reliable and efficient. According to a 2023 report from the Society of Automotive Engineers, modern synthetic oils and advanced engine coatings have extended oil change intervals by up to 50% compared to a decade ago. That’s a direct result of lessons learned from those early experiments.

Could Future Engines Ever Ditch Oil Completely?

Never say never. Materials science is advancing at a breakneck pace, and electric vehicles are already changing the way we think about car maintenance. Some researchers are exploring nano-coatings and smart lubricants that could one day make oil changes a thing of the past. But for now, oil remains the unsung hero under the hood.

The big takeaway? Chasing the oil-free engine isn’t about perfection—it’s about smarter adjustments. Start with one change this week, and you’ll likely spot the difference by month’s end. Sometimes, the road to revolution is paved with small, steady improvements.