Why Are American Automakers Like Ford Still Feeling the Sting of Tariffs?

You might think that building cars right here in the United States would shield automakers from the headaches of international tariffs. After all, if the assembly lines are humming in Michigan or Kentucky, shouldn’t that mean fewer worries about trade wars or import taxes? Yet, even icons like Ford are finding themselves caught in the crosshairs of global tariff battles. So, what’s really going on?

How Do Tariffs Impact Car Companies That Build in the USA?

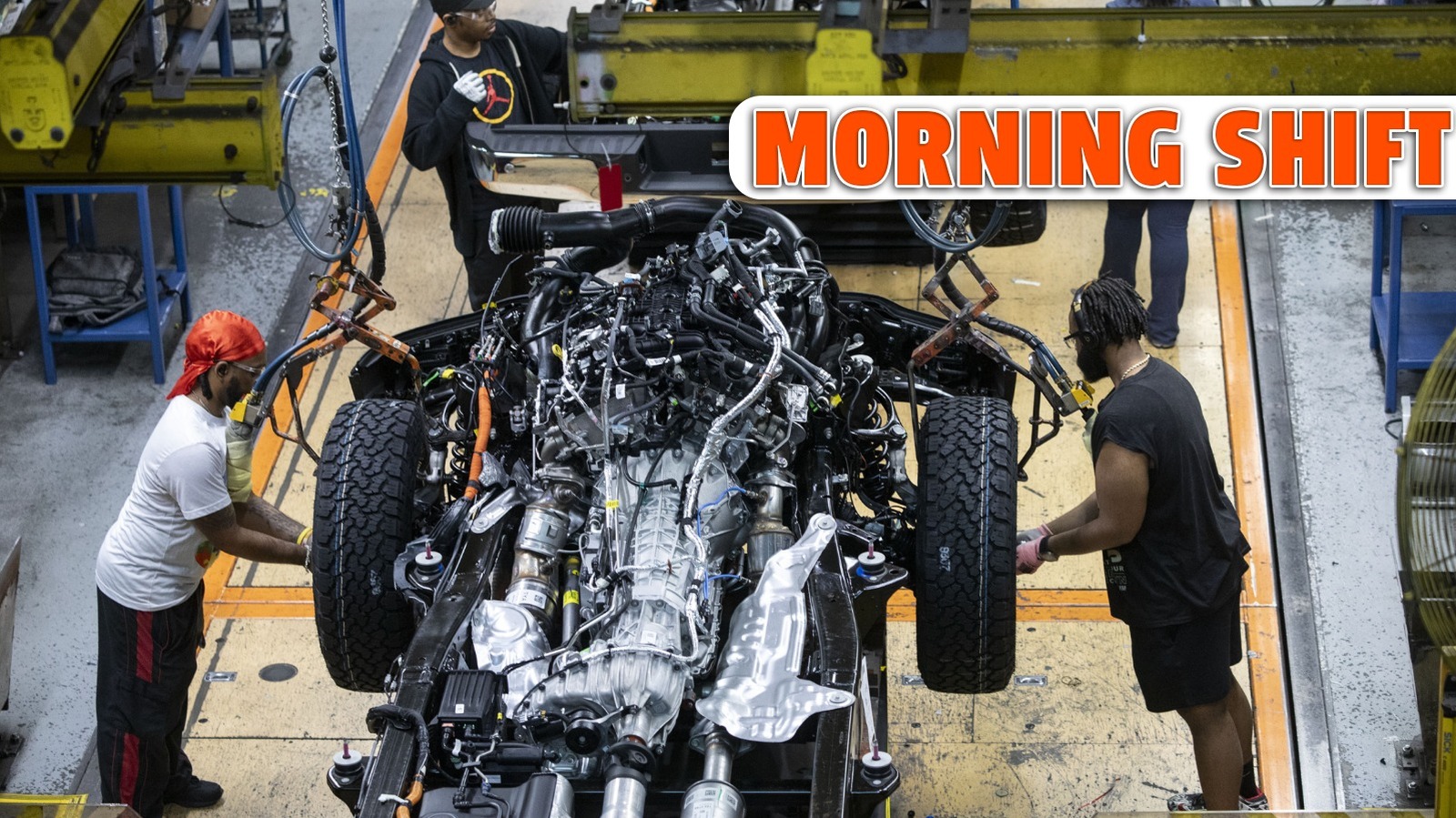

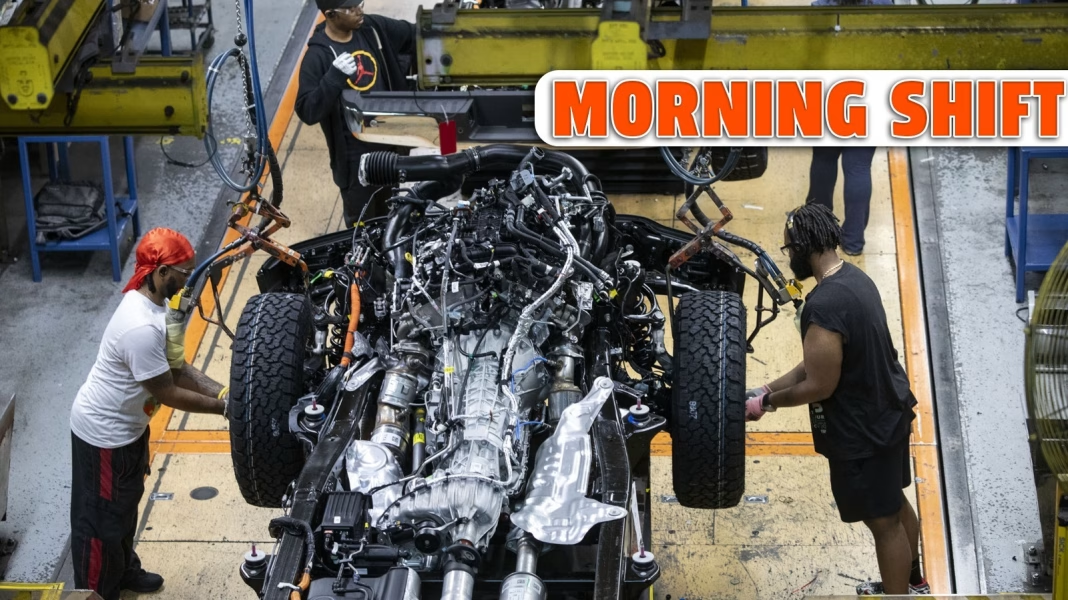

It’s easy to assume that “Made in America” means immune to tariffs, but the reality is far more tangled. Modern cars are a patchwork of parts sourced from all over the globe. Even if a vehicle rolls off an American assembly line, its engine might come from Canada, its electronics from Mexico, and its steel from Europe or Asia. According to the Center for Automotive Research, the average car contains components from at least a dozen different countries.

When tariffs hit imported steel, aluminum, or specific auto parts, the cost of building a car in the U.S. climbs—sometimes by hundreds or even thousands of dollars per vehicle. Ford, for example, has publicly estimated that tariffs on metals alone have cost the company over a billion dollars in recent years. That’s not chump change, and it’s a big reason why American automakers can’t just sidestep the impact.

Why Can’t Automakers Just Switch to Domestic Suppliers?

If tariffs make imported parts expensive, why not just buy American? It’s not that simple. The global supply chain is a finely tuned machine, and switching suppliers isn’t like swapping out a lightbulb. Domestic alternatives may not exist for some high-tech components, or they might be significantly more expensive. Plus, retooling factories and retraining workers to handle new parts takes time and money.

A 2023 report from the Alliance for Automotive Innovation found that nearly 40% of the value of a typical American-assembled vehicle still comes from outside the U.S. That’s a huge chunk, and it highlights just how interconnected the industry has become.

What Does This Mean for Car Prices and American Jobs?

Tariffs don’t just squeeze automakers—they ripple out to consumers and workers, too. When production costs rise, companies have to make tough choices. Sometimes, that means raising sticker prices. Other times, it means cutting corners elsewhere, like delaying new model launches or trimming the workforce.

A study by the Peterson Institute for International Economics estimated that tariffs on imported auto parts could add up to $2,000 to the price of a new car. For families already stretching their budgets, that’s a real hit. And for workers, the uncertainty can mean fewer hours or even layoffs if companies need to tighten their belts.

Are There Any Silver Linings or Solutions on the Horizon?

It’s not all doom and gloom. Some automakers are using this moment to rethink their supply chains, investing in more domestic manufacturing and forging new partnerships closer to home. There’s also a growing push for innovation—think electric vehicles and advanced manufacturing techniques—that could help American companies stay competitive, even in a world of shifting trade policies.

Still, the road ahead isn’t smooth. Navigating tariffs requires agility, creativity, and a willingness to adapt. Ford and its peers are learning that lesson the hard way.

What’s the Real Lesson for Car Buyers and Industry Watchers?

Here’s the bottom line: Building cars in America doesn’t make automakers immune to the global forces shaping the industry. Tariffs are just one piece of a much bigger puzzle, and their effects can be felt everywhere from the factory floor to the showroom.

The big takeaway? Surviving in the auto industry isn’t about perfection—it’s about smarter adjustments. Start with one change this week, and you’ll likely spot the difference by month’s end.