How Can a Small-Block Engine Be So Big?

It sounds like a contradiction, right? The term small-block conjures up images of compact V8s tucked neatly under the hood, but the reality is a bit more nuanced. Small-block engines are defined less by their physical size and more by their architecture—think bore spacing, deck height, and the way the block is cast. Over the years, engineers have pushed the limits of what a small-block can be, squeezing out more displacement and power than anyone thought possible. The result? Some small-blocks that rival their so-called big-block cousins in sheer size and output.

What Sets a Small-Block Apart From a Big-Block?

Let’s clear up the confusion. The classic distinction between small-block and big-block engines isn’t just about cubic inches. It’s about the engine’s basic design. Small-blocks typically have a shorter deck height (the distance from the crank centerline to the top of the cylinder block), narrower bore spacing, and a more compact overall footprint. Big-blocks, on the other hand, are built for brute force, with wider spacing and taller decks to accommodate massive pistons and longer strokes.

But here’s the twist: as technology advanced, manufacturers found ways to increase the displacement of small-blocks without crossing into big-block territory. This meant stroking the crankshaft, boring out the cylinders, and using high-strength materials to keep everything together. Suddenly, a small-block could pack a serious punch—sometimes even out-muscling a big-block in the same car.

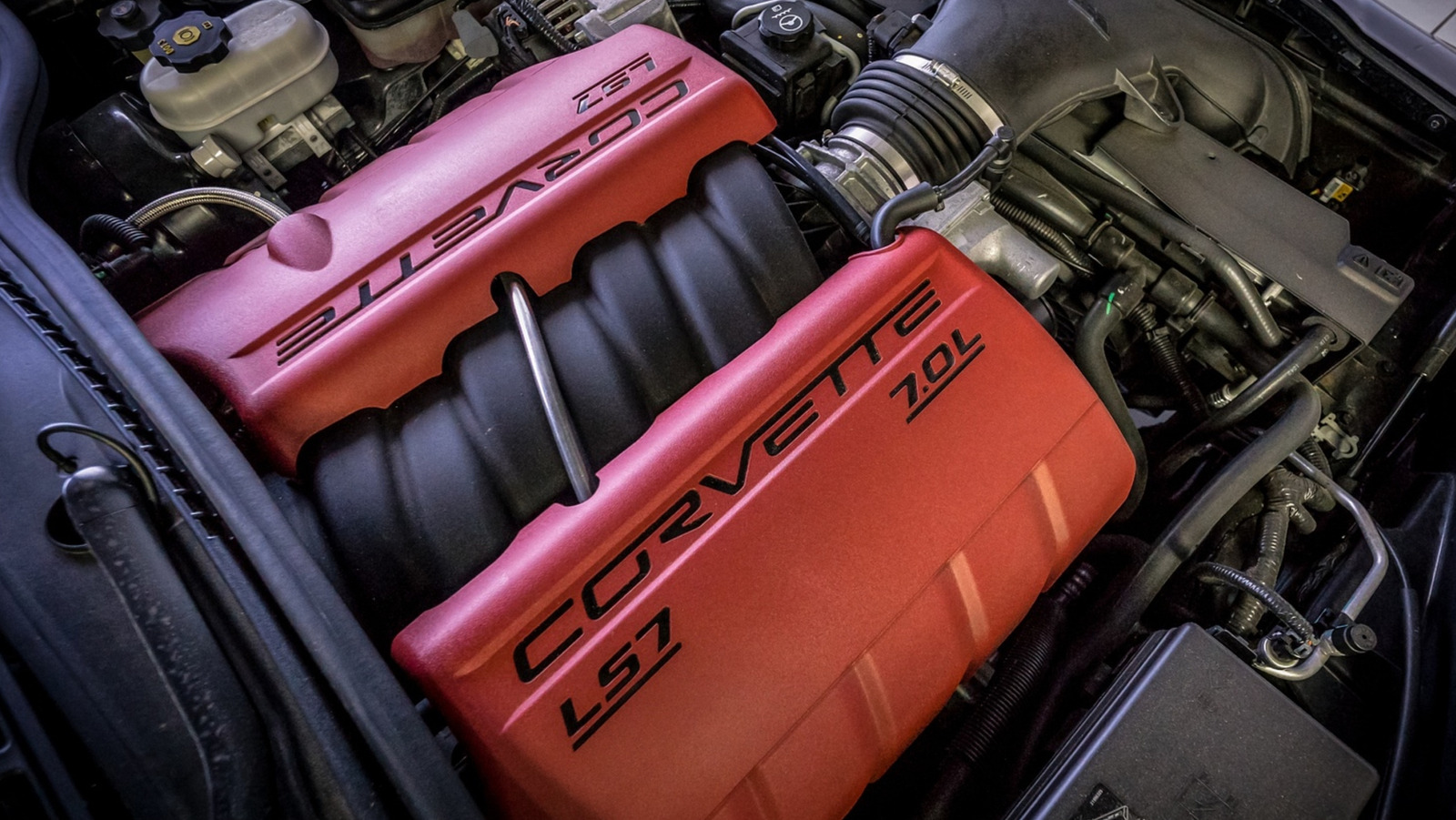

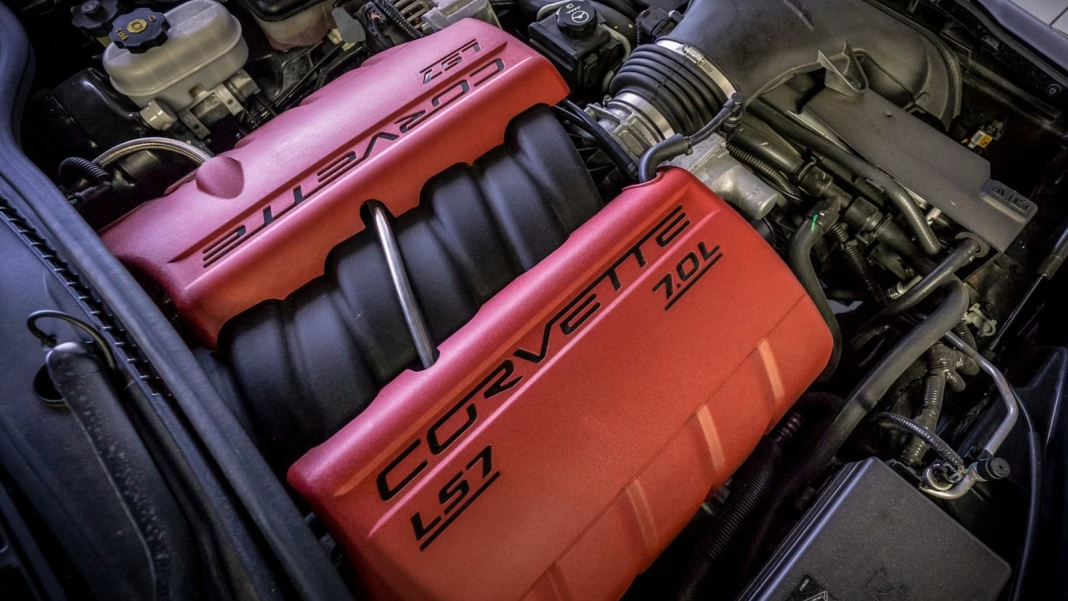

Which Small-Block Engines Are the Biggest Ever Built?

Let’s talk numbers. Among the most legendary large-displacement small-blocks is the Chevrolet 454 cubic inch (7.4L) small-block, a custom build that matches the displacement of Chevy’s iconic big-block. Another monster is the 427 cubic inch (7.0L) small-block, often seen in high-performance drag racing and pro-touring builds. Ford fans might point to the 427 Windsor, a stroked and bored version of the classic 351 Windsor, which can reach up to 460 cubic inches (7.5L) with aftermarket parts.

What’s wild is how these engines maintain the small-block’s lighter weight and compact dimensions, making them ideal for street cars, drag racers, and even restomods. The secret? Modern metallurgy, precision machining, and a willingness to push the envelope.

Why Do Builders Choose Large Small-Blocks Over Big-Blocks?

It’s all about balance. Large small-blocks offer a sweet spot between power and practicality. They’re lighter than big-blocks, which means better weight distribution and handling—especially important if you want your muscle car to do more than just go fast in a straight line. Plus, small-blocks tend to be easier to fit into a wider variety of vehicles, thanks to their more compact size.

There’s also a nostalgia factor. Many hot rodders grew up with small-block Chevys or Fords and love the idea of wringing every last drop of performance out of a familiar platform. And let’s be honest—there’s something deeply satisfying about surprising people with what looks like a “little” engine that absolutely hauls.

Are There Downsides to Building a Massive Small-Block?

Of course, nothing’s perfect. Pushing a small-block to big-block displacements can stress the engine’s architecture. Thin cylinder walls, increased heat, and higher internal pressures all become concerns. Builders need to invest in high-quality parts—think forged pistons, billet cranks, and reinforced blocks—to keep everything together at high RPMs.

Cost is another factor. While small-blocks are generally less expensive to build and maintain, going for maximum displacement can quickly add up, especially if you want reliability to match the power.

What Do the Experts Say About These Engines?

Engine builders and performance shops have weighed in over the years. According to data from the Specialty Equipment Market Association (SEMA), demand for high-performance small-block components has steadily increased, with stroker kits and aftermarket blocks among the top sellers. Experts like David Freiburger, editor at large for a leading automotive publication, have noted that modern small-blocks can easily produce 600-800 horsepower on pump gas with the right combination of parts.

Real-world results back this up. At events like Hot Rod Drag Week, you’ll find cars running massive small-blocks that consistently outperform their big-block rivals, both in elapsed time and reliability. It’s a testament to how far engine technology has come.

How Do These Engines Perform on the Street and Track?

Here’s where things get fun. A well-built large-displacement small-block delivers instant throttle response, a broad torque curve, and enough horsepower to embarrass plenty of modern sports cars. On the street, you get the drivability and lighter weight that makes daily cruising enjoyable. At the track, you get the kind of acceleration that pins you to the seat.

Take, for example, a 454-cubic-inch small-block Chevy in a classic Camaro. With modern fuel injection and a well-tuned suspension, it’s not just fast—it’s civilized. You get the best of both worlds: old-school rumble and new-school reliability.

What Should You Consider If You Want to Build One?

If you’re thinking about building a big small-block, start with a solid foundation. Aftermarket blocks from reputable manufacturers like Dart or World Products are designed to handle the extra stress. Invest in quality rotating assemblies, and don’t skimp on cooling or oiling systems. Work with a machine shop that understands the unique challenges of large-displacement small-blocks.

And don’t forget about the rest of the car. Upgraded brakes, suspension, and drivetrain components are a must if you want to safely harness all that power.

The Big Takeaway

Small-block engines aren’t about fitting into a box—they’re about pushing boundaries. The biggest small-blocks prove that you don’t need a massive engine bay to make serious power. It’s not about perfection—it’s about smarter adjustments. Start with one change this week, and you’ll likely spot the difference by month’s end.